Drilling steps out further along Red Metal’s unique, potentially low-cost rare earths project

Mining

Mining

Special Report: An extensive 10,000m step-out drill program is underway on economic portions of Red Metal’s new Sybella rare earth oxide (REO) discovery, 20km southwest of Mount Isa in northwest QLD.

Red Metal (ASX:RDM) reckons it might have a “world first” on its hands; a new rare earths deposit style that’s extensive and cheap to mine and process.

Sybella is a unique, partially weathered and fresh REO-enriched granite >12km-long and 3km-wide that offers vast tonnage potential with high concentrations of valuable magnet rare earths such as neodymium, praseodymium, dysprosium and terbium in the overall REO content.

Initial Metallurgical test work on the granite found that the REO content was extractable using sulphuric acid at ambient temperature and offers scope for processing using “heap leach methods with the potential for highly competitive capital and operating costs”.

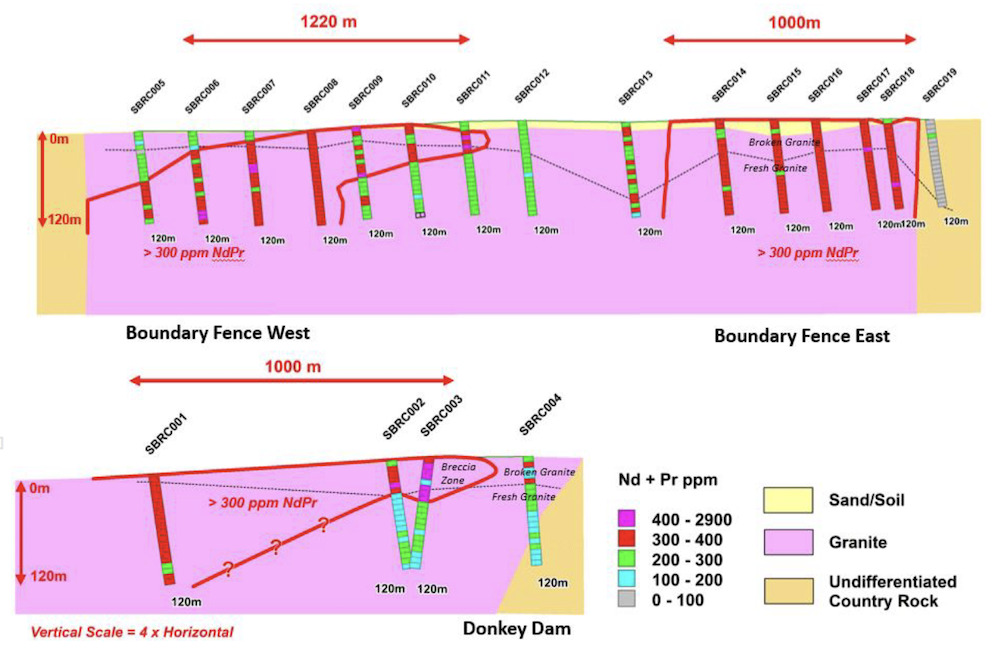

An initial Phase 1 RC drill program discovered large widths of granite-hosted REO mineralisation with wide zones of >300 ppm NdPr oxide starting at surface.

Although limited by the number of drill lines, three broad areas of interest were identified – Boundary Fence East, Boundary Fence West and Donkey Dam.

Subsequent ambient temperature leach test work by ANSTO demonstrated that strong REO extractions can be achieved on coarse non-pulverised, RC chip samples with low levels of sulphuric acid consumption.

RDM says it points to the opportunity for simple, low-cost REO processing potentially involving heap leach methods that avoid the need for extensive crushing.

The current Phase 2 drilling will initially cover an 8 x 3km area of Sybella with 60m deep holes spaced on 800 x 200m and 800 x 400m centres.

The program will account for some 150 holes and ~10,000m of drilling designed to test the grade of REOs and any metallurgical variability across this portion of the granite.

AC drilling will provide non-pulverised, weathered granite to bit refusal while percussion drilling will extend these holes to 60m acquiring fresh granite for analysis.

“Work this year will seek an effective process for REO extraction and provide a more certain indication of the size and grade potential of this exciting new REO discovery,” the explorer says.

“Optimised Phase 2 leach tests, purification studies on the Pregnant Leach Solutions (PLS), comminution studies and step-out drilling are progressing.”

Results from the current Phase 2 leach test work evaluating the leach responses for a range of size fractions under varying acid strengths and over extended residence times are expected shortly.

This article was developed in collaboration with Red Metal, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.