Lafarge to roll out Zimbabwe’s first 3D concrete homes

By Sifelani Tsiko

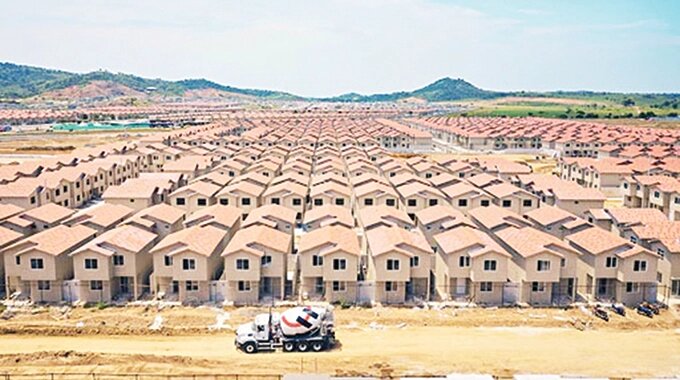

In one of the quickest paths from imagination to built options —Lafarge Cement Zimbabwe will soon deliver innovative solutions using 3D — concrete printing technology to build houses and schools as part of efforts to address the country’s chronic shortage of housing and school infrastructure.

The company which is part of global concern LafargeHolcim, is innovating and is seizing opportunities in the 3D printing market by developing specific construction solutions to reduce its carbon footprint and spur Zimbabwe’s housing development agenda.

“To showcase the capabilities of 3D printing, Lafarge Cement Zimbabwe will construct 10 units in Knockmalloch under the affordable housing project currently underway. This project will afford relevant stakeholders to witness and experience the capabilities of this and innovative technology and it is anticipated that this will attract more projects towards the use of the technology to provide decent affordable housing,” the company said recently when President Mnangagwa commissioned the Dry Mortar Plant constructed at a cost of US$2,8 million.

This technology was developed by LafargeHolcim through its subsidiary 14 Trees and the new dry mortar mix plant will be producing the required 3D printing ink for local projects.

The 3D printing technology uses computer-aided design (CAD) to create three-dimensional objects through a layering method.

It simply involves layering materials, like plastics, composites or bio-materials to create objects that range in shape, size, rigidity and colour.

The process consists of a printer with a robot with a mechanical arm that can move on a track in different directions to lay mortar in a pattern on a print-bed as designed on a computer.

The dry mortar in a silo is mixed with water in a mixer and pumped via a hose to a nozzle mounted on the end of the robot arm.

A 3D printed home can be completed in just 12 hours, compared to four days using normal construction methods.

The company says the technology can reduce its carbon footprint by up to 70 percent, helping Zimbabwe and other African countries on the project to fight climate change.

A school and house was printed in Malawi in a first for Africa under the first phase of a project which will be rolled out to Kenya and Zimbabwe.

In principle, experts say houses “printed” in this way can be built much faster and with more flexibility than traditional models.

They further say that less concrete is needed, helping to reduce cost and promote sustainable housing construction approaches.

“3D printing technology offers a range of benefits which makes it a viable alternative construction technique for affordable housing. The benefits include increased construction speed, up to 50 – 70 percent faster than conventional method, enhanced sustainability as less materials are used (50mm thick walls versus 140mm) and affordability as construction costs are estimated to come down as much as 10-20 percent,” the company said in statement.

The new technology was developed at LafargeHolcim’s R&D centre to promote innovation to develop affordable homes and innovative housing concepts. This technology is setting the tone for the future and a modest house can be developed at a cost of US$10 000.

It aims to cut construction time and reliance on carbon — heavy resources in line with sustainable development goals. The project — 14Trees is a joint venture between LafargeHolcim and the UK’s development finance institution, CDC Group.

According to media reports, CDC Group, funded by the UK government, is expected to invest more than R30 billion in Africa and Asia as part of its push towards fighting climate change and creating job opportunities in 2021. The Herald