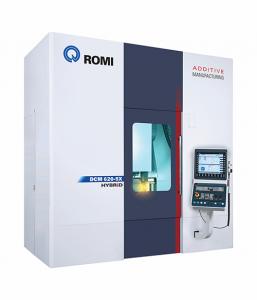

Romi's DCM 620-5X Hybrid Vertical Machining Center Allows 5-Axis Additive or Subtractive Machining

Engaging all three linear axes and the tilting (B) and rotating (C) axes allows simultaneous machining on all five axes.

ERLANGER, KY, UNITED STATES, March 3, 2021 /EINPresswire.com/ -- Romi USA has introduced the DCM 620-5X Hybrid 5-Axis vertical machining center with additive and subtractive machining capabilities. Engaging all three linear axes and the tilting (B) and rotating (C) axes allows simultaneous machining on all five axes. The machine combines millesimal angular positioning with high rigidity to enable very precise machining of highly complex parts. The DCM 620-5X Hybrid is one of Romi's complete line of hybrid manufacturing machine tools that combine traditional machining operations with 3D metallic additive manufacturing.

The machine is built on a Romi-made monoblock base and has a net weight of 20,300 lbs. It features linear roller guides for the X, Y, and Z axes and direct rotary encoders for the B and C axes. This combination reduces vibration and produces high rigidity and precision.

The DCM 620-5X Hybrid also features a 40 big-plus taper direct-drive spindle capable of 15-15,000 rpm, a 24 hp motor, a 24" x 20" x 18.1" table (X, Y, Z), and a 30-tool automatic tool changer. It is equipped with a Siemens Sinumerik 840D sl CNC that features a 19" touch screen.

Romi has made switching back and forth from subtractive machining to additive manufacturing as simple as making a tool change. Once the additive head is brought into position via an automatic tool changer, the laser deposition - additive process on the workpiece can begin. Material can then be added to the piece in the exact profile, amount and location desired. It is ideal for part repair, adding features, or intricate work where subtractive manufacturing takes more time and produces more wasted material. The machine gives users the ability to add high-cost materials such as Inconel and stainless steel in the exact amount required to achieve the desired profile while minimizing material costs.

According to Mr. Rafael Boldorini, General Manager at Romi USA, "As with all of our products, the newest generation DCM 620-5X Hybrid was designed and built based on extensive customer research. It will offer users higher productivity, robustness, and precision."

About Romi Machine Tools Ltd

Romi Machine Tools Ltd is based in Erlanger, KY, and is a wholly-owned subsidiary of Brazilian based Industrias ROMI S.A. Serving the USA and Canada, Romi Machine Tools Ltd offers customers a line of innovative and robust machine tools including CNC lathes, turning centers, and vertical machining centers. All the key parts used to build a Romi machine tool, including the base castings, are made at the company's state-of-the-art manufacturing facility in Santa Barbara d'Oeste, Brazil. This control over all key components allows Romi to build a particularly rigid, accurate and high-performance solution.

Romi Machine Tools Ltd, also known as Romi USA, maintains a showroom and full parts and service department at its Erlanger location. Its machine tools are available through a network of direct sales personnel and regional distributors. For more information on Romi's products and solutions, visit www.romiusa.com.

About Industrias Romi S.A.

Founded in 1930, Industrias Romi S.A. is the market leader in the Brazilian machinery and industrial equipment market, and a major manufacturer of cast iron and machined parts.

Romi manufactures machine tools, including mechanical lathes, CNC lathes, turning centers, vertical milling machines, vertical lathes, heavy-duty and extra heavy-duty lathes, and horizontal milling machines. The company also manufactures plastic injection molding and plastic blow molding machines, as well as nodular and vermicular grey cast iron supplied rough or machined.

The company's products and services are commercialized globally and are used in diversified industrial segments including light and heavy automotive, agricultural machinery, aerospace, medical, capital goods, consumer goods, tooling, hydraulic, and wind power.

The company is listed on Novo Mercado, a listing segment of BM&F Bovespa for the trading of shares issued by companies that commit themselves voluntarily to adopt corporate governance practices in addition to those that are required by law.

Rafael Boldorini

Romi Machine Tools Ltd

+1 859-647-7566

rboldorini@romiusa.com

Visit us on social media:

Facebook

Twitter

LinkedIn

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.