Chemtech company announces next generation, PFAS-free molecular adhesive

Innovative design eliminates “forever chemicals” without compromising performance

The new crosslinker and surface treatment solution, known as BondLynx BXW-202, has been rebuilt from the ground up to eliminate fluorine from its chemical structure. The result is an adhesive that is safer for the environment, more stable for storage, and more cost-effective for customers.

Unlike traditional adhesives that rely on mechanical forces to hold materials together, BondLynx employs bis-diazirine technology to create covalent bonds between polymer chains, permanently crosslinking them through strong carbon-carbon bonding. Originally designed to bond “unbondable” low surface energy plastics like polypropylene and polyethylene, BondLynx has since found applications as a surface functionalizing agent, an additive in microelectronics fabrication, a performance textile strengthener, and a molecular stabilizer for perovskites, quantum dots, and organic electronics.

Until now, fluorine - one of the most reactive elements in the periodic table - was considered a critical component of bis-diazine crosslinking. But with the tide turning against the use of PFAS chemicals, the development of a suite of fluorine-free products was the company’s top priority.

“With all we now know about the persistence of PFAS chemicals in the environment, it was important for us to get ahead of the problem and be a part of the solution,” stated Director of Strategy, Sean Bourquin. “Our clients have been telling us the same thing. This issue is on everyone's radar these days, so we knew we had to find a new formula for BondLynx.”

To accomplish this goal, the R&D team at XLYNX Materials went back to the drawing board to create a version of BondLynx that did not depend on fluorine.

“To be honest, we weren’t sure whether a fluorine-free crosslinker with the adhesive strength of the original BondLynx would be possible,” admitted Senior Research Chemist, Dr. Rashid Nazir. “It was uncharted territory, but being innovative is what our team has always done best.”

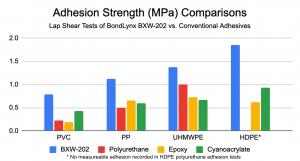

While he did not reveal details about the solution they designed, Dr. Nazir reported that test results for the new molecular adhesive have exceeded expectations. In comparative lap shear adhesion tests with conventional polyurethane, cyanoacrylate, and epoxy adhesives, BondLynx BXW-202 outperformed the competition in every category.

“It’s exciting to see how well it’s performing,” Sean Bourquin commented. “To be able to eliminate PFAS chemicals, add stability, and drive down costs, all without compromising the quality of BondLynx adhesion, is a remarkable achievement that we can all be proud of.”

XLYNX Materials is now capitalizing on its innovative platform technology to design a suite of PFAS-free crosslinkers for specific substrates and client applications. The company encourages new and existing clients to reach out for information on how BondLynx BXW-202 can address their manufacturing needs, unlock new opportunities, and support their move towards a more sustainable future. Learn more at www.xlynxmaterials.com/abetterbondlynx/

XLYNX Materials Inc.

XLYNX Materials is an innovative chemtech company located in Victoria, BC, Canada, specializing in crosslinking solutions that transform the properties of low surface energy materials. The company is the global leader in the field of materials-based diazirine crosslinking and works with industry leaders and innovative researchers from around the world to address long-standing challenges in a broad range of manufacturing applications. XLYNX’s diazirine crosslinking technology has been featured in numerous peer-reviewed academic journals, including Science, and the company was recently awarded a 2023 Innovation Award by the Adhesive and Sealant Council (ASC), joining past winners that include DuPont, Dow, PPG, and Avery Dennison.

For information and sales, visit www.xlynxmaterials.com or contact info@xlynxmaterials.com.

David Thickens

XLYNX Materials Inc.

david.thickens@xlynxmaterials.com

Visit us on social media:

Facebook

Twitter

LinkedIn

Distribution channels: Chemical Industry, Electronics Industry, Energy Industry, Manufacturing, Science

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release