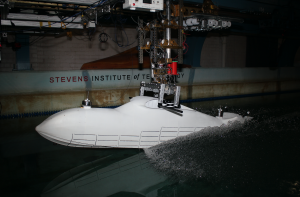

Tidal Flight Tests First 3D Printed Model in Davidson Laboratory’s High Speed Towing Tank at Stevens Institute of Technology

RICHMOND, VA, UNITED STATES, December 18, 2024 /EINPresswire.com/ -- Hampton, Virginia-based Tidal Flight, Inc. recently conducted towing tank testing of a 1/6th scale prototype of their 9-12 passenger seaplane in collaboration with the Davidson Laboratory at Stevens Institute of Technology. Tidal Flight’s 1/6th scale seaplane model is the first 3D-printed model tested at the Davidson Laboratory, marking a valuable technological milestone for both Tidal Flight and the Davidson Laboratory.

Tidal Flight is an early-stage startup developing Polaris, a modern, clean-sheet, hybrid-electric seaplane that can carry 9-12 passengers and is capable of landing on waterways and runways alike. “There is a recognized gap in regional air mobility, specifically around trips of 100 to 500 miles that are often served poorly by conventional airlines,” said Jude Augustine, Co-Founder and CEO of Tidal Flight. “At Tidal, we identified a unique opportunity to address this need with a modern, clean-sheet, hybrid-electric seaplane, providing direct and sustainable access to coastal communities and city centers.”

Founded in 1935, the Davidson Laboratory is one of the largest and most widely renowned hydrodynamic and ocean engineering research facilities in the nation, conducting physical experiments on marine craft to determine how they interact with their environment. Originally proposed to study seaplane dynamics, the Davidson Laboratory’s High-Speed Towing Tank, measuring 313 feet long, 16 feet wide, and 6 feet deep, is the ideal facility to understand seaplane takeoff and landing characteristics.

“The Davidson Laboratory High-Speed Towing Tank was built in 1944 with US Navy’s support to conduct tests of large systematic series of seaplane designs,” said Dr. Raju Datla, research associate professor at Stevens. “We are very pleased to see the resurgence of these vessels and excited to continue our legacy and work with Tidal Flight and the new generation of innovators.”

Tidal Flight fabricated a 1/6th scale (10 foot length) flying demonstrator of Polaris using the Selective Laser Sintering (SLS) 3D printing method and executed flight tests in July of 2024. “This unique method of manufacturing enables rapid iteration of complex hull forms and aircraft shapes at reduced labor and cost,” said Pranav Krishnamurthy, Co-Founder and CTO at Tidal Flight. “The result was the ability to design, build, and fly our 1/6th model in less than five months with just our three co-founders.”

Using the 3D-printed fuselage of the 1/6th scale demonstrator as the towing tank model, Tidal Flight conducted seaplane porpoising, resistance, and directional stability tests at the Davidson Laboratory. These tests marked the first fully 3D-printed model to be tested at Davidson Laboratory, validating that 3D printing can meet the geometric accuracy, structural, weight, and surfacing requirements to enable accurate and reliable data collection. In collaboration with Tidal Flight, the Davidson Laboratory is exploring the use of 3D printing for future towing tank models to make complex hull designs easier to manufacture and to reduce labor required for model building.

The towing tank testing conducted in collaboration with the Davidson Laboratory is a key milestone in Tidal Flight’s aircraft development. “Monohull seaplane design has not seen significant improvements since the 1950s,” said Mark Lau, Co-Founder and Chief Engineer at Tidal Flight. “We are seeking to modernize seaplane design using modern computational methods to reduce aerodynamic drag, enabling high fuel efficiency and range.” Towing tank testing is critical to the validation of computational methods since the high-speed planing regime during takeoff and landing is particularly challenging to analyze. Additionally, Krishnamurthy noted, “Underwater and overwater photography from towing tank testing has already provided critical insights on flow behavior and spray characteristics that are informing the next iteration of our hull design.” The initial towing tank test campaign completed in October provides valuable data that Tidal Flight is using to drive design iteration on the hull of their aircraft, with plans to return to the towing tank with an updated design in 2025 incorporating learnings from the initial testing.

Tidal Flight’s testing program was funded by a Virginia Innovation Partnership Corporation (VIPC) Commonwealth Commercialization Fund (CCF) grant. The CCF grant has enabled Tidal Flight to fabricate subscale prototypes of the aircraft, execute flight testing of the prototypes, and perform the aforementioned towing tank tests. These efforts serve to de-risk and validate the technology while attracting new customers and investors.

“This highly talented and motivated team demonstrates exceptional dynamics, technical expertise, and a well-defined plan to advance their groundbreaking technology,” said Jeanette Townsend, VIPC’s Director of Private Sector Grants. “Tidal Flight’s innovative hybrid-electric seaplane aligns perfectly with CCF’s funding priorities, serving as a strong proof-of-concept project that paves the way for further development, follow-on funding opportunities, and a higher likelihood of commercial success. We are proud to have Tidal Flight as an outstanding addition to the CCF portfolio.”

About Tidal Flight

Tidal Flight is a Hampton Roads, Virginia-based startup that builds aircraft to make air travel sustainable and affordable. Tidal Flight’s first aircraft is a hybrid-electric amphibious aircraft to unlock direct, affordable, and sustainable access into city centers and coastal communities. For more information, visit www.tidalflight.com.

About Stevens Institute of Technology Stevens Institute of Technology is a premier, private research university situated in Hoboken, New Jersey. Since our founding in 1870, technological innovation has been the hallmark of Stevens’ education and research. Within the university’s three schools and one college, more than 8,000 undergraduate and graduate students collaborate closely with faculty in an interdisciplinary, student-centric, entrepreneurial environment. Academic and research programs spanning business, computing, engineering, the arts and other disciplines actively advance the frontiers of science and leverage technology to confront our most pressing global challenges. The university continues to be consistently ranked among the nation’s leaders in career services, post-graduation salaries of alumni and return on tuition investment.

About Virginia Innovation Partnership Corporation (VIPC)

Connecting innovators with opportunities. VIPC operates as the nonprofit corporation on behalf of the Virginia Innovation Partnership Authority (VIPA). VIPA / VIPC is Virginia’s designated authority for leading innovation and economic development in the Commonwealth of Virginia through research, commercialization, and technology advancement; entrepreneurship, startup, and venture capital growth; and regional ecosystem, innovation network, and industry sector expansion. As part of its operations, VIPC helps attract and catalyze private investment into early-stage startup companies, provides research and technology commercialization grants to universities and entrepreneurs, and offers resource and funding support for entrepreneurial ecosystems, innovation networks, and public-private partnerships at local, state, federal levels.

VIPC’s programs include: Virginia Invests | Virginia Venture Partners (VVP) | Commonwealth Commercialization Fund (CCF) | Entrepreneurial Ecosystems Development | Regional Innovation Fund (RIF) | Smart Communities | The Virginia Smart Community Testbed | The Virginia Unmanned Systems Center | Virginia Advanced Air Mobility Alliance (VAAMA) | The Public Safety Innovation Center (PSIC) | Federal Funding Assistance Program (FFAP) for SBIR & STTR | University Partnerships | Startup Company Mentoring & Engagement.

For more information, please visit www.VIPC.org. Explore the latest news from VIPC and images from VIPC-supported stakeholder events. Follow VIPC on Facebook, X, and LinkedIn.

Angela Costello, Vice President of Communications

Virginia Innovation Partnership Corporation (VIPC)

angela.costello@VirginiaIPC.org

Visit us on social media:

Facebook

X

LinkedIn

Distribution channels: Aviation & Aerospace Industry, Business & Economy, Companies, Culture, Society & Lifestyle, Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release