Extreme-condition plastics: sustainable and flame-retardant

GA, UNITED STATES, February 25, 2025 /EINPresswire.com/ -- A new recyclable poly (imide-imine) plastic has been developed, offering a sustainable solution for industries reliant on high-performance materials. This innovative polymer combines exceptional mechanical strength, thermal stability, and chemical resistance, while being chemically recyclable. It addresses the long-standing challenge of recycling polyimides, a material typically difficult to recycle, especially in sectors such as aerospace, defense, and electronics.

In fields like aerospace, defense, and electronics, high-tech plastics like polyimides have become essential due to their outstanding mechanical strength, thermal stability, and chemical resistance. However, these very properties make them difficult to recycle. Their high melting points and chemical stability pose challenges for traditional recycling methods, leading to significant waste and environmental concerns. As the global plastic crisis intensifies, the demand for sustainable alternatives that retain these critical properties while being easily recyclable has never been more urgent.

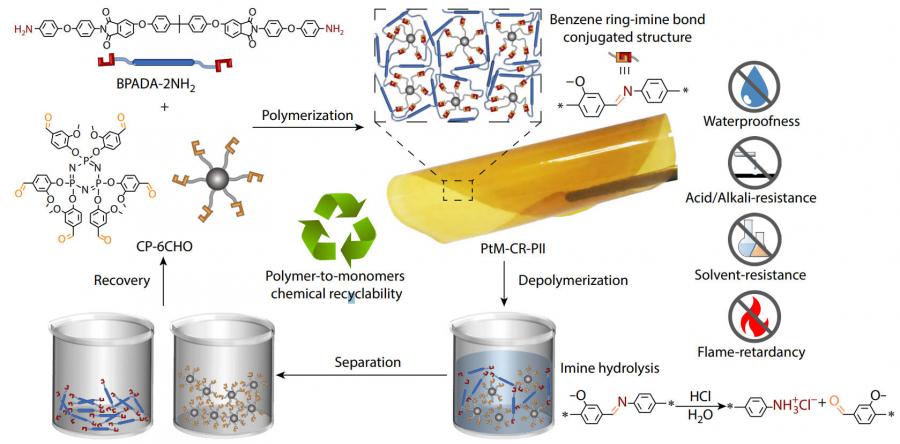

A team of researchers from Jilin University recently published a major study (DOI: 10.1007/s10118-024-3199-0) in the Chinese Journal of Polymer Science on September 2, 2024, presenting a new recyclable poly(imide-imine) plastic. This novel material, polymer-to-monomers chemically recyclable poly(imide-imine) (PtM-CR-PII), can be easily depolymerized into its original monomers, enabling a closed-loop recycling process that reduces waste and promotes environmental sustainability.

The PtM-CR-PII plastic is synthesized through a cross-linking reaction between amine-terminated aromatic bisimide (BPADA-2NH2) and hexa-vanillin-terminated cyclophosphazene (CP-6CHO) monomers, utilizing dynamic imine bonds. This innovative structure endows the material with impressive mechanical and thermal properties. PtM-CR-PII shows a Young’s modulus of 3.2 GPa, a tensile strength of up to 108 MPa, and a glass transition temperature of around 220°C—comparable to, or even exceeding, the performance of traditional polyimides. The material also exhibits exceptional resistance to harsh conditions, maintaining its mechanical integrity after exposure to water, concentrated acids and bases, and various organic solvents. This durability is attributed to the rigid, hydrophobic aromatic imide groups and benzene ring-imine conjugated structures within its backbone. Additionally, the plastic’s flame resistance is outstanding, with a UL-94 V-0 rating and a limiting oxygen index (LOI) of 45.5%.

The key innovation lies in its chemical recyclability. PtM-CR-PII can be depolymerized at room temperature using an organic solvent-acid mixture, yielding high-purity monomers (over 95%) with a recovery rate exceeding 80%. These monomers can be reused to produce new PtM-CR-PII plastic, ensuring a sustainable closed-loop recycling process that minimizes waste and promotes environmental sustainability.

Professor Xiao-Kong Liu, the lead researcher, emphasized the importance of this advancement, “Our PtM-CR-PII plastic not only meets the rigorous demands of aerospace and defense applications but also addresses environmental concerns through its recyclability, supporting a shift toward a circular economy for high-performance.”

The development of PtM-CR-PII plastic represents a significant step forward for industries that depend on high-performance materials. Its combination of mechanical strength, thermal stability, and flame retardancy, coupled with its recyclability, makes it a sustainable alternative to traditional polyimides. This innovation could lead to more environmentally responsible practices in manufacturing, reduce waste, and foster a circular economy in material science.

DOI

10.1007/s10118-024-3199-0

Original Source URL

https://doi.org/10.1007/s10118-024-3199-0

Funding information

This work was financially supported by Natural Science Foundation of Jilin Province (No. ***202302003), National Natural Science Foundation of China (No. 22275069) and National Key R&D Program of China (No. 2023YFA1008804).

Lucy Wang

BioDesign Research

email us here

Distribution channels: Chemical Industry, Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release